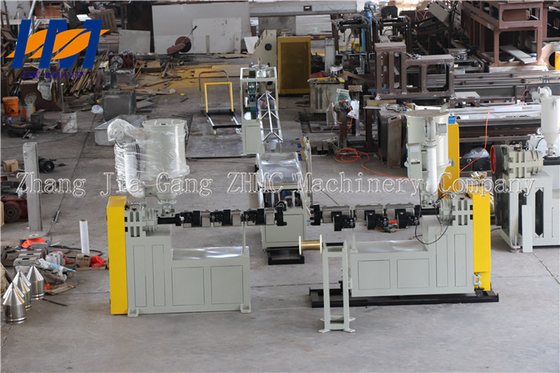

PVC Corner Bead Plastic Making Machine plastic extrusion products

PVC Corner Bead Plastic Making Machine Main Features

1. The High Pressure Flexible Polystyrene PU Air tubes Extruder is simple structure ,easy in installation and maintenance.

2. The PU air tube extruder adopts advanced world famous brand components in hydraulic parts ,electric parts and operation parts.

3. The air tube extruder is energy saving, high productivity , good plasitcization and refined glue quality characteristic.

4. The flexible air tube extruder can be equipped with various extrusion heads as required by users.

5. A machine body temperature measuring and indicating device is installed.The feeding zone is equipped

with side rolls for the enhancement of feeding capability.

6. The screws and bushes are subjected to nitrogenation treatment to get enough strength and wear-resistance.

7. The reducer has a forced lubrication unit,which is featured by high transmission efficiency,long service life and low noise.

8. The machine is driven by a variable-speed motor.

9. The side rolls are designed as side-open type for easy rubber removal.

Extruder

Extruder Its special extruding screw systems , precise manufacturing data , temperature controls and speed adjusting systems ensure stable good extruding ;

Dies

Dies Excellent Cr-plated heat resistant steel alloy is applied for T-dies , which flowing channels are of clothes-hanger type design , with excellent flow distributing systems , to make sure that flows can go evenly to all the whole dies ; A adjusting system equipped onto up and down die lips , to make sure that all sheets have good thicknesses ;

Vacuum forming tank

Vacuum former Vacuum system and forming system are well designed and located ; equipped with a quick heat exchange die , forming systems and cooling system is well and precisely located among vacuum systems in good orders ; vacuum systems are composed of 2 independent sub-systems , each of them are equipped with many triangle type close-circuit vacuum tubes ; all close circuit systems are equipped with vacuum conditioning and monitoring systems , to make sure to have a stable and even vacuum degree on all sheet surfaces ;

Haul-off machine

Haul-off machine The 1st one is big power and of big decelerate ratio , equipped with many rollers , it has a excellent low speed working , while its big hauling-off can draw sheets evenly out from vacuum former ; The 2nd haul-off draws sheets out from heating oven ; The 3rd and 4th haul-off are for transmission and unloading ;

Heating oven

Heating oven ( annealing oven ) working together with the 1st and 2nd haul-offs , its multi-zones infrared constant temperature heating systems give good annealing to sheets , improving all sheets flatness ;

cutting machine

A precise auto short-time fixed length cutting systems and auto a lift type unloading system are equipped ;

Electronic control

Electronic control both panel control and PLC control systems are chosen

Machine List

| NO. |

Machine Name |

| 1 |

Dust collection mixer |

| 2 |

Conicial twin-screw extruder |

| 3 |

PVC corner bead extrusion mold + vacuum calibration table |

| 4 |

Hau-off machine |

| 5 |

Online punching + cutting + stracker |

Detailed Picture

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!