Plastic sheet making machine plastic extrusion production line pvc wall panel making

Product Application

1. This production line adopts intelligent control and automatic operation.

2. Wallboards of various specifications, sizes, shapes and thicknesses can be produced by replacing different moulds.

3. This wallboard is a new kind of decorative material instead of wall paint and wallpaper.

4. It also has many elements such as environmental protection, heat insulation, moisture-proof, fire protection, sound insulation and fashion.

5. The material is light and easy to install.

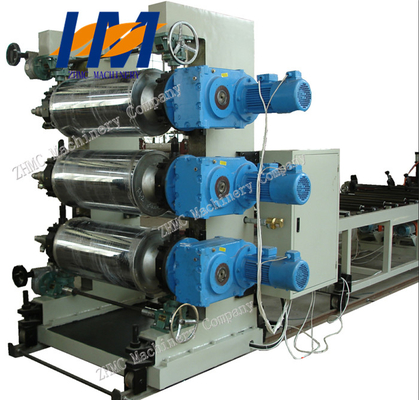

Product Sheet line in detial

Extruder

(1) The screw barrel is made of 38CrMoALA and nitrided by equipments from Zhejiang Zhoushan Weibo Machinery Co., Ltd. PLC Control System

(2) The nitriding depth of screw is 0.4-0.6 mm, the hardness (HV) is 740-940, and the surface roughness Ra is less than 0.8 um.

(3) The nitriding depth of the barrel is 0.5-0.7mm, the hardness (HV) is 940-1100, and the inner wall roughness Ra is less than 0.8um.

(4) The gearbox is vertical split. The gears are treated by 20CrMoTi nitriding and grinding, the gear material of the distribution box is nitrided by 38CrMoAlA, and the shaft is made of 40Cr. The main bearings are domestic famous brand bearings, running smoothly.

There are three different models with different production capacity.

| Extruder Model |

SJ65 |

SJ80 |

SJ100 |

| Motor Power |

VVVF 55 |

VVVF 65 |

VVVF 75 |

| Capacity(kg/h) |

50 |

80 |

110 |

Q1: Are you a factory or trading company?

A:We are the manufacturer and we have over 30 years factory experience .As only the machine made by ourself ,quality can be trusted, and most important thing is we can do better service after sales. we know how to fix the problem in each parts easliy. so welcome to visit to our factory.

Q2: How long is the delivery time?

A:For standard machines, it would be 60 working days; For non-standard machines and customized machines according to client s specific requirements, it would be 90 working days.

Q3: How should I pay for my order ? what is the procession of this purchase?

A:You can do 30% prepayment at first, then we will start to make production. When the machines are ready , we will take pictures and videos to you, and then you can do the balance.After we got your payment. We will send the machine to you.

Q4:How is the machine warranty and after-sale service?

A:All our machine would have a warranty of 12 months since the date of machine installation in client's factory. And beyond warranty period, we can offer spare parts or repair service with or without charges

Product Display

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!